It is no secret that our society would have a hard time operating without some type of fuel source. Whether your vehicle runs on ethanol or gasoline, you would be out of luck if something happened to the nation’s fuel supply.

This is why it can be a great idea to learn how to create your own fuel source at home. You never know when you will need it.

You may be wondering how on earth you are supposed to make your own fuel source; after all, you do not have a drill, and you do not know where any underground oil fields are anyways. Luckily, you can make your own fuel source using just a few simple ingredients.

Keep in mind that this method will only produce a small amount of fuel. If you want to produce on a larger scale, you will need to invest in extra storage space.

To start with, you will need to make sure that you have all of your ingredients and supplies to make this fuel source.

Luckily, there are only three ingredients used in this particular method of creating your own fuel source. This means that it is great for beginners and easy to do.

Here is a list of the ingredients and supplies that you will need:

Now that we have all of our supplies and ingredients, it is time to get started!

1. Start by measuring out 500 ml of the oil of your choice and pouring it into your pan.

Turn on your heat and make sure that you have a thermometer handy to observe the temperature of your oil. After the oil has begun heating, you can move on to the second step.

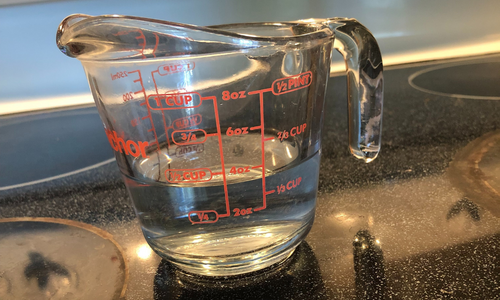

2. For this step, measure out 100 ml of methanol.

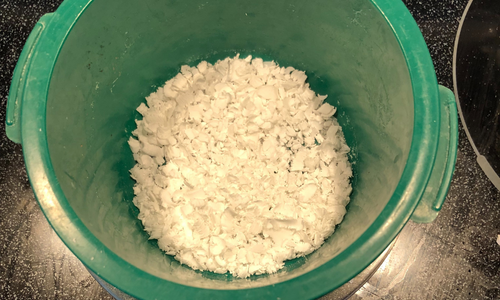

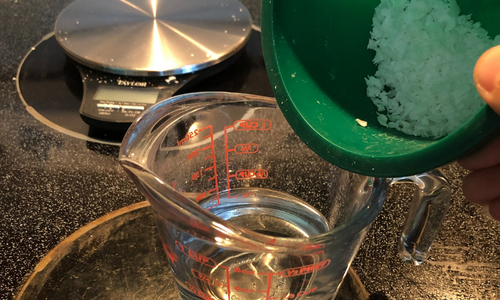

3. Depending on which type of chemical you decided to go with, you will need to measure the correct amount for this fuel recipe to work.

If you have potassium hydroxide, you will need 3.5 grams; if you have sodium hydroxide, you will need 2.8 grams.

When you have the correct amount of chemical measured out, you will need to add it to the methanol that we measured in the previous step.

Simply pour in the chemical and stir until dissolved. This should take no more than 10 or 15 minutes.

Use this time to check the temperature of your oil. The ideal temperature for your oil is 130 degrees. When you reach this temperature, it is time for the next step!

4. It’s time to combine the ingredients in a separate container. Using a funnel, pour your hot oil into a mixing container such as a glass jar. Remember that this oil will be hot, and can burn you, so use extra precautions during the pouring process.

When your hot oil is safely in the mixing container, it is time to pour your chemical/ methanol solution into the oil. Seal the mixing container as tightly as possible and shake this mixture for at least five minutes.

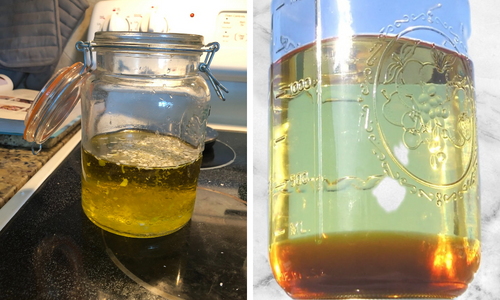

You may notice the mixture changing colors throughout the shaking process; this is normal.

5. After you are done shaking your mixture, find somewhere safe to set your jar and let it set uninterrupted for around 24 hours.

When you come back the next day, you should notice that your mixture looks a little different than it did the day before. Again, this is normal!

Your mixture should be separated into three distinct layers. The top layer should be clear and is the desired biodiesel.

The middle layer is a little more cloudy; this is the glycerin. If you have set the jar in a colder area, you may notice a third layer that is actually the biodiesel gelling.

6. Gently pour out the top layer of glycerin from your mixture, being careful not to pour out any of the biodiesel. Set your jar back in its safe place and let it sit for a few more days. Your mixture should slowly become more and more clear until you can see through it.

Now that you have completed all of the steps, you are left with your very own biodiesel that can be used freely for any small machines that you have around your property. It can also be used to fill up any oil lamps that you have lying around.

Not only is biodiesel easy to make by yourself in small batches, but it is also much better for the environment. Since it is made from plant oils usually, it is considered a renewable alternative to regular diesel.

Not only that, but it is better for emissions and for the environment. It is more easily cleaned up in the case of a spill, and it is also far less combustible than normal diesel.